Thermal Infrared Inspection

Detecting Problems Early

Service Electric offers thermal infrared inspection services for hospitals, factories, and other industrial facilities. Thermal infrared technology is typically utilized for electrical, mechanical, and building envelope inspections.

Power Distribution Inspections

Electrical infrared inspection is a critical component of predictive maintenance operations on power distribution equipment. Inspections will:

- Locate Anamalies

- Prevent Failures

- Improve Safety

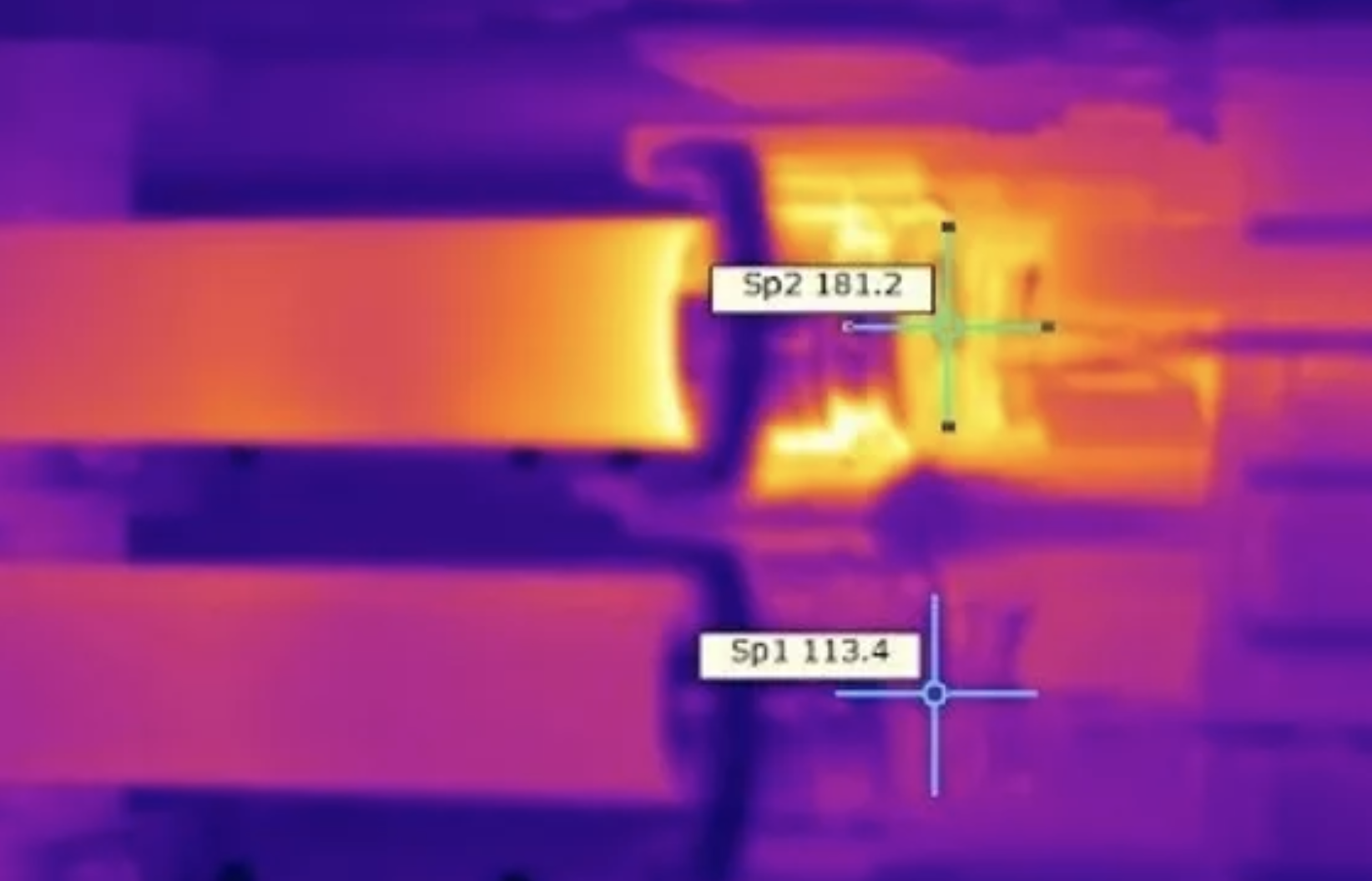

Electrical Infrared

The purpose of thermal infrared inspection is to locate problems in their early stages. Failing components, high-resistance connections, and load imbalances can lead to serious damage and costly downtime. Non-contact ultrasound is also employed in electrical inspections to locate potential failures due to corona, arcing, and tracking conditions.

Mechanical Infrared Inspections

Mechanical infrared inspection is integral to current and ongoing monitoring of mechanical infrastructure. Infrared inspection will:

- Locate Anamalies

- Prevent Failures

- Capture Baseline

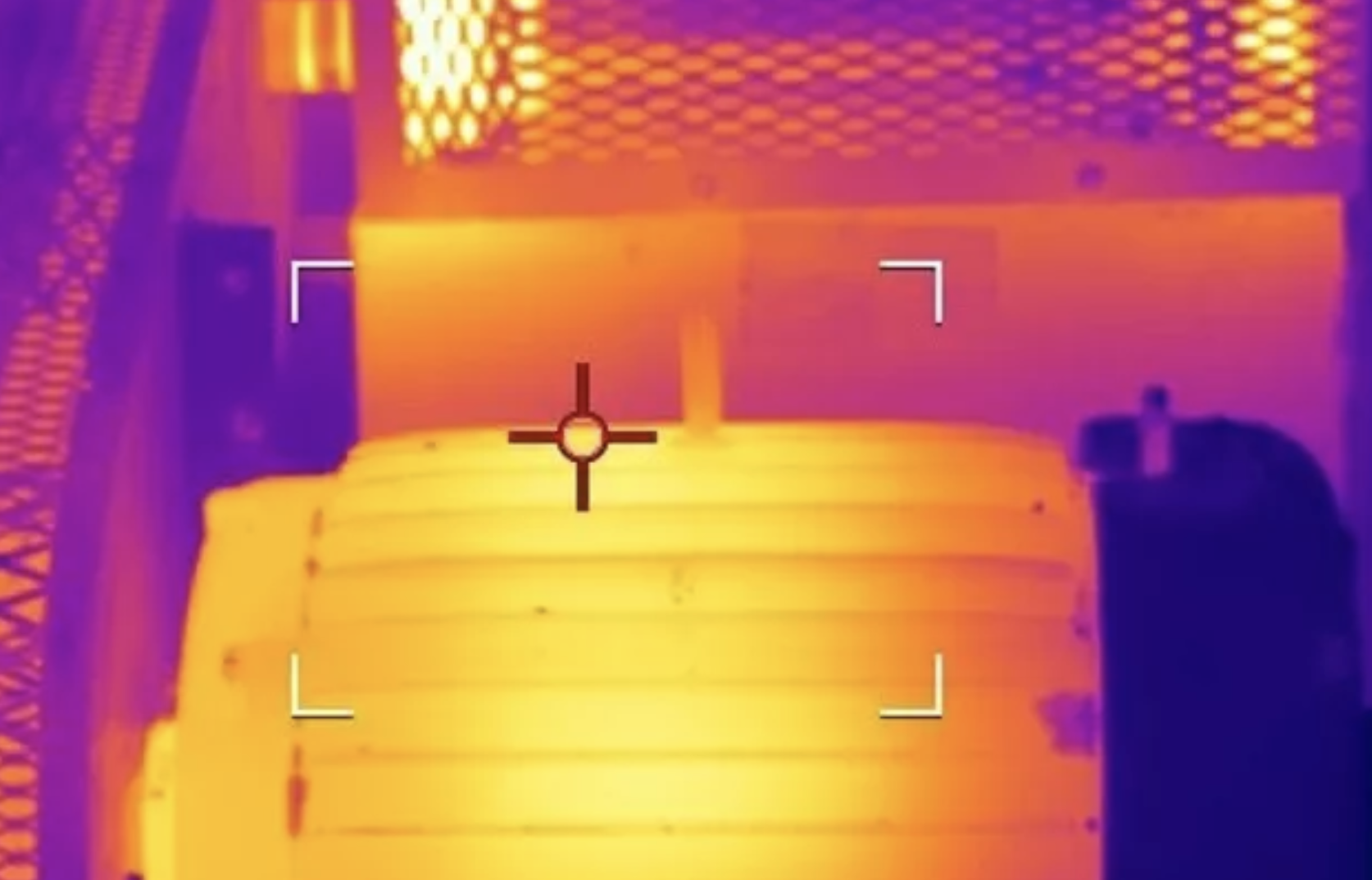

Mechanical Infrared

The purpose is to locate problems developing before failures occur. Excess heat degrades equipment. The inspection establishes a thermal baseline as well as immediate concerns that need to be addressed. Contact ultrasound on equipment is also employed to help identify developing problems and potential failures to equipment while under load.

Flat Roof Inspections

Infrared inspection discovers common flat roof problems and will provide:

- Early Leak Detection

- Locate Sub Surface Moisture

- Warranty Protection

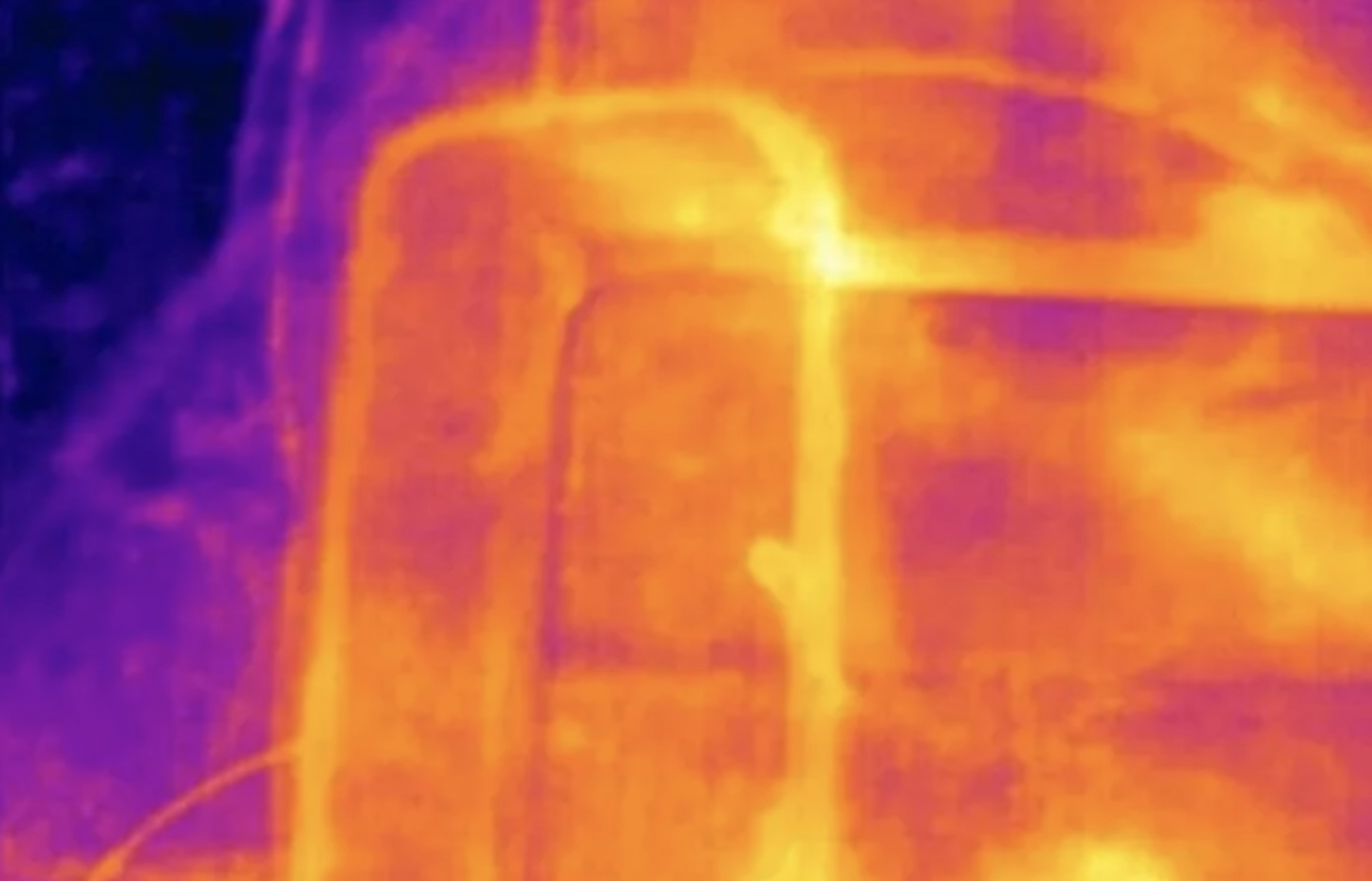

Flat Roof Inspection

Roof structures are one of the costliest parts of a building. Flat roof infrared inspections pinpoint leak locations, and future leak locations in sub-surface layers from cracks and entry points. A flat roof will hold moisture creating leaks unless it can evaporate. Flat roof inspections locate these ‘hot’ spots; which are then marked and mapped for repair thus avoiding costly repairs and damage to a facility and its contents.

What to Look for in an Infrared Inspection Service?

Infrared imagers used in predictive maintenance should be FPA (focal plane array) systems that use a matrix of detectors to sense thermal radiation. The result is data that offers better resolution providing a quality image. Infrared inspections are able to detect high resistance electrical connections, excess heat in mechanical equipment, and critical conditions in buildings and operations. If performed correctly, infrared inspections are non-destructive, non-contact, and provide valuable information. The infrared imager requires proper set-up of emissivity, transmissivity, reflectivity, humidity, temperature range, focus, and distance for a quality inspection of an asset. Routine inspections allow for baselines to be monitored as well as detection of immediate concerns to avoid catastrophic failures. The entire process reduces repair costs, extends equipment life, increases efficiencies, and saves energy.